|

Copper Roof Vents

Slant Back Copper Roof Vent

Ventilation for asphalt, slate, copper,

metal and tile roofs

|

|

|

|

| All

Copper Construction |

16" x

20.313" x 5" |

8"

Weather-Tight Seamed Collar |

Fits

All Pitched Roofs |

Copper Static Air Roof Vent Provides 50 NFA (in.²)

Per Vent

Three Sides Louvered for greater air

flow and bird-proof protection.

Add a backdraft damper to almost any roof

vent

Plastic construction, will not rust! Prevents

corrosion of dissimilar metals at connection.

|

|

Exhaust vent adapter fits 3" or 4" flexible duct.

10” nailing flange. |

Installs from top of deck or inside of attic

to roof vent. |

Call 1-800-685-8263 or e-mail us at

info@volko.com ]

There is a silent war underway in most

attics and crawlspaces. Insulation, structure, paint and roofing materials are

under attack from heat and moisture. Excessive heat buildup can top 150º

degrees Fahrenheit in an attic. Excessive moisture can actually condense to

water droplets. The only way to get rid of damaging heat and moisture is with a

proper ventilation system of intake and exhaust ventilators. Left unventilated,

heat and moisture can wreak havoc in a home, causing expensive damage. With a

proper ventilation system of intake and exhaust vents, hot humid air is

continually replaced by fresh air, removing excessive heat and moisture.

|

How do

ventilators work?

Is a vent just

a vent? |

|

Ventilation products are all too often

considered a commodity. The lack of proper knowledge leads to the belief

that all cornice vents are alike; a roof louver is a roof louver; there is

no difference between vents, possibly other than price. In truth, however

there is a substantial difference in products.

Product Design - Ventilation

products are designed to achieve two major functions -

capacity to ventilate and weather protection.

1. Capacity To Ventilate -

Intake and roof exhaust are determined by four factors:

A. Thermal Effect - The air

outside of the attic is always colder than the air inside the attic.

Hot air does not rise - cold air pushes it. The opening available

on the cornice vent determines the amount of cold air allowed to

push hot air upward. The exhaust capabilities are determined by the

flue or stack of the exhaust ventilator. The process works much

like a chimney or stove pipe. Using roof louvers as an example,

compare various products and their flue or collar.

B. Wind Pressure - Outside air

moving across the exhaust ventilator creates a pressure difference

causing the ventilator to draw depending on design. Product design

determines true exhaust capabilities.

C. Centrifugal Force - This

capability can only be implemented by an electric power source or

wind rotary action. Longevity of the products to perform this

action is key in understanding this ventilation approach.

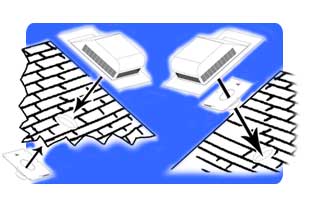

D. Location on the Roof - The

above factors discussed are positively influenced by application of

the vent on the top one-fourth section of the roof.

2. Weather Protection - The

capacity to ventilate is of utmost importance; however, weather

protection cannot be sacrificed. Weather infiltration develops the

main enemy in the attic, moisture. Product comparison in the field

demonstrates this major factor.

Summary:

There is a great difference in ventilation products available in the

marketplace. The low cost of ventilation relative to the value

enhancement dictates using the most functional products available.

courtesy of http://www.lomanco.com

|

Call 1-800-685-8263 or e-mail us at

info@volko.com

...for all those things you thought were not available in copper.

|